Processing and Manufacturing Technology

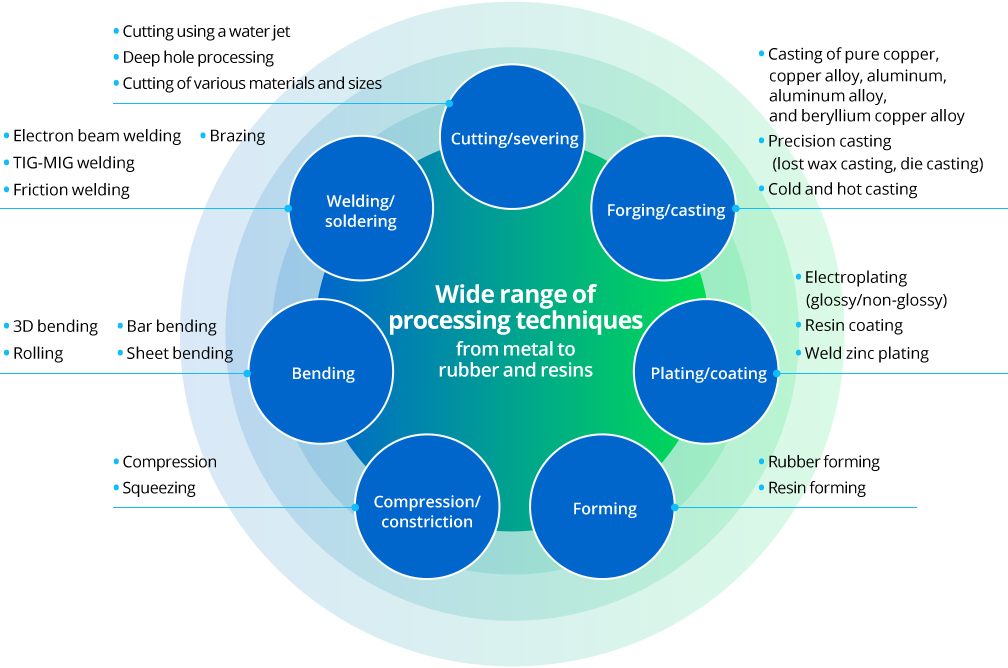

Evolving our products through seven basic techniques

Pursuing customer satisfaction through processing technology based on material knowledge

One strength is advanced metal processing and insulation processing based on our extensive knowledge of materials ranging from metals to rubber and resins. We respond to customer requests by making full use of our seven basic techniques of cutting, casting, coating, plastic forming, compression, bending, and welding, and by striving to make daily improvements. Achieving customer satisfaction is the essence of the manufacturing pursued by FEPS. In design and development, we select the most suitable materials and structures according to the functions required of the product. In production technology and manufacturing, we pursue high levels, high added value, and high quality. Recently, we are also focusing on providing safe, secure, and highly workable products that fully utilize new materials such as polymers and silicones.

Customized products

In addition to existing products, FEPS develops and manufactures products to meet customer needs.

Please give us a description of the product that you desire.

We perform integrated production that encompasses all phases from product design to material procurement, products, quality assurance, and shipping.

Basic techniques

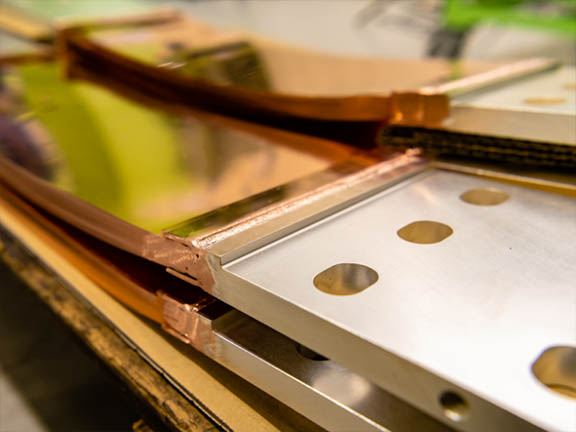

Forging/casting

- Casting of pure copper, copper alloy, aluminum, aluminum alloy, and beryllium copper alloy

- Precision casting (lost wax casting, die casting)

- Cold and hot casting

Techniques for molding metal into a desired shape

FEPS possesses casting and forging techniques centered on copper alloys. We can handle various materials such as pure copper, copper alloys, beryllium copper alloys, high-strength brass, aluminum, and aluminum alloys. Our extensive knowledge of material properties enables us to provide optimal products by considering usage, economic efficiency, and productivity.

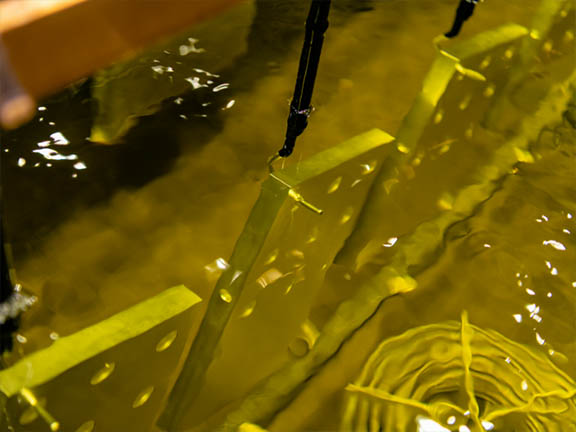

Cutting/severing

- Cutting using a water jet

- Deep hole processing

- Cutting of various materials and sizes

Techniques for cutting various materials

FEPS possesses cutting techniques for various materials. In regard to cutting metals, especially copper and copper alloys, we have accumulated an abundance of processing technology that considers every detail, from the selection of machines to the manufacture of jigs and tools, the cutting conditions, the shapes of tools and tips, and the cutting oil.

Welding/soldering

- Electron beam welding

- TIG-MIG welding

- Friction welding

- Brazing

Outstanding techniques and skill in welding non-ferrous metals

When joining metals, it is important to select a welding method that matches the application and function. By fully utilizing various joining methods such as gas welding, arc welding, resistance welding, electron beam welding, diffusion bonding, and friction welding, FEPS is able to precisely meet customer requirements for precision, strength, electrical characteristics, airtightness, and more

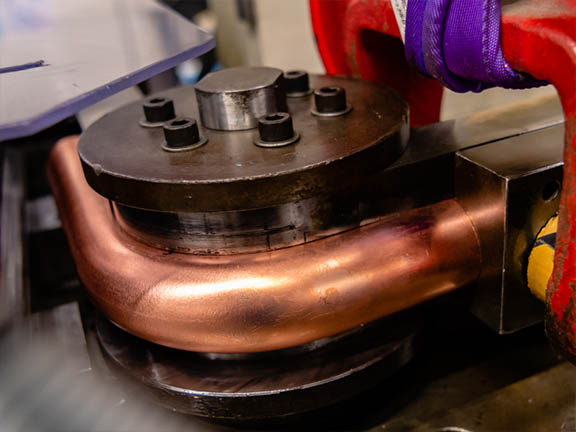

Bending

- 3D bending

- Rolling

- Bar bending

- Sheet bending

Advanced techniques that consider the strength and elasticity of materials

For bending, the jigs and tools to be used and the optimum processing method differ depending on the material and the required shape. FEPS responds to various requests by fully utilizing our processing know-how and techniques according to the material (pipes, bars, etc.) and shape (thickness, outer diameter, etc.).

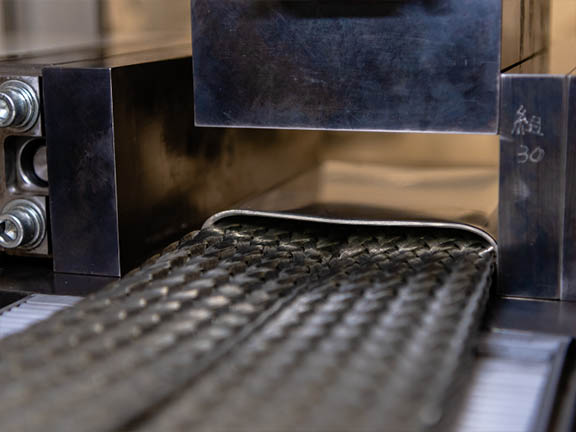

Compression/constriction

- Compression

- Squeezing

Techniques for utilizing presses

The functionality of products can be enhanced by using compression to combine different materials. FEPS has presses ranging from 100 tons to 1,000 tons. For squeezing, we fully utilize all kinds of equipment and technology, from manual drawing to spinning machines, to process thin plates, tubes, and other shapes made of various materials including copper, aluminum, and brass. We offer products in a variety of shapes.

Forming

- Rubber forming

- Resin forming

Techniques that integrate insulating rubber, semi-conductive rubber, and metal

FEPS selects the optimal materials from among a variety of materials by considering characteristics such as insulation, weather resistance, waterproofness, flame retardancy, and oil resistance. We are able to respond to a wide range of high-level requests by selecting methods that include injection forming, pressing, and forming with plastisol.

Plating/coating

- Electroplating (glossy/non-glossy)

- Resin coating

- Weld zinc plating

Diverse techniques for plating and coating

Our coating techniques include electroplating (gold, silver, copper, tin, nickel, zinc, chromium), electroless plating (nickel, solder, tin), hot-dip plating (zinc, solder), and copper electroforming. We contribute to the improvement of product performance by selectively using methods including painting, chemical conversion treatment, resin coating, and alumite treatment in accordance with the application and characteristics.