Heat conductive sheet

Peace of mind through siloxane-free heat countermeasures

Product overview

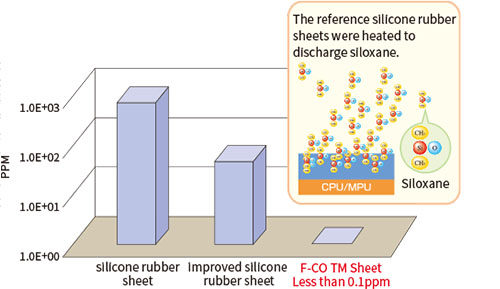

- Siloxane-free

TM sheet does not generate low-molecular-weight siloxane which causes problems such as contact failure and optical lens clouding.

Amount of detected siloxane

- (Note) Values were measured using a method selected by FEPS

- Environmental friendly

All TM Sheets comply with environmental regulations such as ROHS, REACH, and North American TSCA. The sheets do not contain the hazardous substances halogen, lead, and chlorofluorocarbon. - Low VOC (volatile organic compounds)

Materials and manufacturing methods that generate lower emissions are used. The amount of gas generated is less than that of typical thermal conductive sheets.

Reduces the risk of corrosion of components (connectors, wiring, etc.) and clouding of optical components.

VOC generation amount

- Low oil bleed

Lower oil bleeding than typical silicone products. - Easy handling

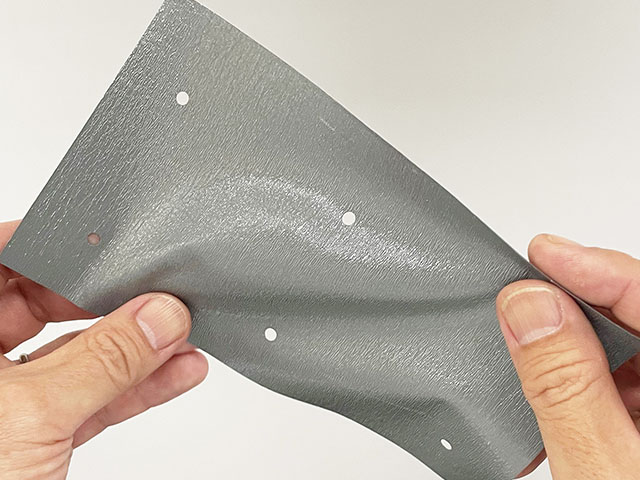

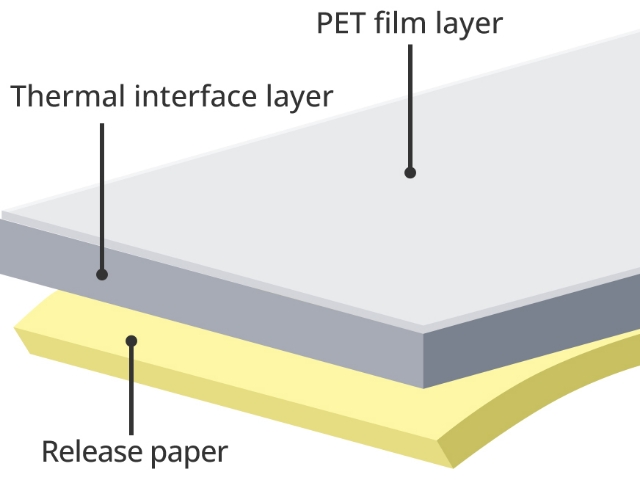

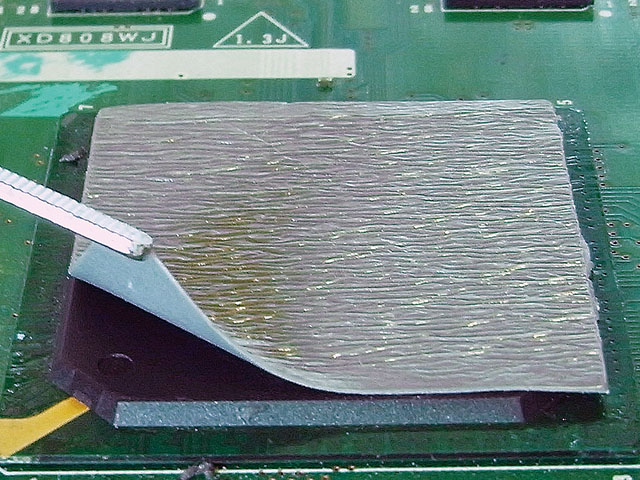

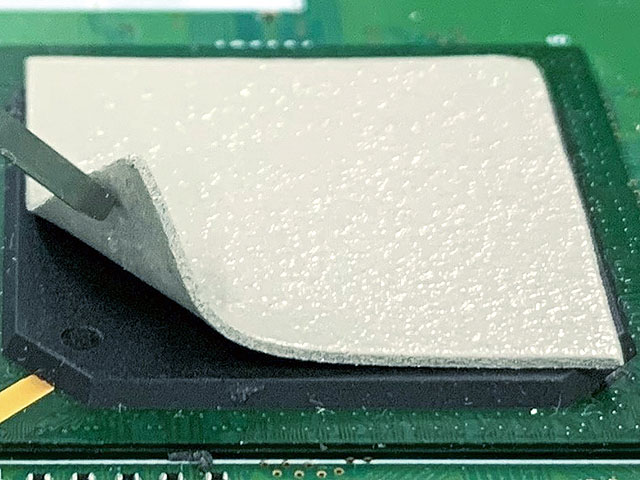

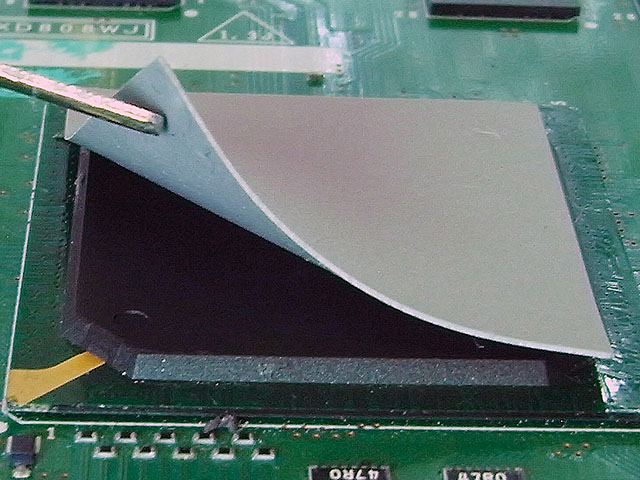

The two-layer structure of a thin PET film and main layer achieves durability and easy handling (for VHT, VFT, EE-RT).

- (Note) Do not remove the PET film.

- (Note) The PET film is somewhat wrinkled during the manufacturing process. The wrinkles are smoothed when pressure is applied, so there is virtually no effect on heat resistance.

Use

- General industrial use

High-performance printers, semiconductor manufacturing equipment, optical equipment, communication equipment, measuring equipment, liquid crystal displays, LED lighting, servers, storage, etc. - Automobile use

Automotive navigation systems, various control devices, hybrid/EV power supplies, cameras, etc. - Digital devices use

Computers, digital cameras, HDDs, TVs, video games, etc.

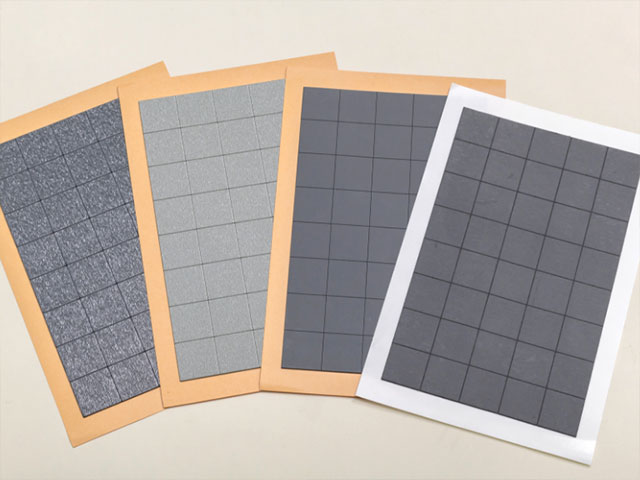

Lineup

Standard type: EE-RT

The sheet has a two-layer structure consisting of an acrylic body and a PET film. The sheet is rigid, possesses high thermal conductivity, and is easy to handle.

The thickness is 0.3mm, which is the thinnest among non-silicon products. This creates an advantage in terms of thermal resistance.

Properties

Scroll right to view more information

| Thickness*1 (mm) |

Thermal conductivity (W/m-K) |

Hardness*2 (Asker C) |

Volume resistivity (Ω-cm) |

Dielectric breakdown (kV/mm) |

Flame retardancy | Temperature range*3 (°C) |

Density | ||

|---|---|---|---|---|---|---|---|---|---|

| Min | Max | ||||||||

| EE-RT | 0.3 | 8.0 | 3.0 | 50 | 1 x 1010 | 10 | V-0 | -40 - 120 | 2.6 |

| Measurement standards | JIS B 7503 | JIS R 2616 | JIS K 7312 | JIS K 6911 | JIS K 6911 | UL 94 (file No. E210580) |

FEPS standards | JIS Z 8807 | |

- *1 Thickness is in intervals of 0.5 mm (1.5 mm, 2.0 mm etc.).

- *2 Hardness (Asker C) is measured 15 seconds after contact based on JIS specifications (15-second value). Please contact us for the numerical value at the time of contact (0-second value).

- *3 The heat resistance temperature is determined based on changes in factors such as hardness and differs depending on usage conditions.

- (Note) These are measured values and are not guaranteed.

High heat conductive type: VHT

This sheet has a two-layer structure consisting of a main body made of thermoplastic elastomer and a PET film. It has the highest thermal conductivity of any non-silicon sheet.

Properties

Scroll right to view more information

| Thickness*1(mm) | Thermal conductivity (W/m-K) |

Hardness*2 (Asker C) |

Volume resistivity (Ω-cm) |

Dielectric breakdown (kV/mm) |

Flame retardancy | Temperature range*3 (°C) |

Density | ||

|---|---|---|---|---|---|---|---|---|---|

| Min | Max | ||||||||

| VHT | 0.5 | 4.0 | 4.5 | 45 | 1 x 1012 | 6.5 | V-0 | -40 - 120 | 2.5 |

- *1 Thickness is in intervals of 0.5 mm (1.5 mm, 2.0 mm etc.).

- *2 Hardness (Asker C) is measured 15 seconds after contact based on JIS specifications (15-second value). Please contact us for the numerical value at the time of contact (0-second value).

- *3 The heat resistance temperature is determined based on changes in factors such as hardness and differs depending on usage conditions.

- (Note) These are measured values and are not guaranteed.

Soft type: VFT

This sheet has a two-layer structure consisting of a main body made of thermoplastic elastomer and a PET film. It possesses excellent flexibility.

The sheet is designed to alleviate compressive load on the substrate and parts, absorb the gap tolerance between the object and the radiator, conform to undulations when adhered to an uneven surface, and reduce thermal resistance due to close contact.

Properties

Scroll right to view more information

| Thickness*1(mm) | Thermal conductivity (W/m-K) |

Hardness*2 (Asker C) |

Volume resistivity (Ω-cm) |

Dielectric breakdown (kV/mm) |

Flame retardancy | Temperature range*3 (°C) |

Density | ||

|---|---|---|---|---|---|---|---|---|---|

| Min | Max | ||||||||

| VFT | 0.5 | 4.0 | 2.5 | 22 | 1 x 1013 | 6.0 | V-0 | -40 - 120 | 2.5 |

- *1 Thickness is in intervals of 0.5 mm (1.5 mm, 2.0 mm etc.).

- *2 Hardness (Asker C) is measured 15 seconds after contact based on JIS specifications (15-second value). Please contact us for the numerical value at the time of contact (0-second value).

- *3 The heat resistance temperature is determined based on changes in factors such as hardness and differs depending on usage conditions.

- (Note) These are measured values and are not guaranteed.

Hard type: HF

We also offer hard type HF.

Properties

Scroll right to view more information

| Material/feature | Thickness*1(mm) | Thermal conductivity (W/m-K) |

Hardness value at 15 secs*2 (Asker C) |

Flame retardancy | Tacky side*3 | ||

|---|---|---|---|---|---|---|---|

| Min | Max | ||||||

| HF | Polyolefin: hard film type | 0.5 | 1.2 | 95 | V-0 | Both the front side and back side are non-tacky. (Note) We also offer tape that is tacky on one side. |

|

- *1 Thickness is in intervals of 0.5 mm (1.5 mm, 2.0 mm etc.).

- *2 Hardness (Asker C) is measured 15 seconds after contact based on JIS specifications (15-second value). Please contact us for the numerical value at the time of contact (0-second value).

- *3 The tacky side of TM Sheet does not adhesive; however, it has the inherent tackiness of rubber. This makes the sheet slightly adhesive. (HF-N is a non-adhesive film type that is basically non-adhesive, but can be coated with adhesive on one side as an option).

- (Note) These are measured values and are not guaranteed.

Thermal performance test method

Thermal conductivity

Thermal conductivity is measured in accordance with the hot-wire method defined by JIS-R2616 using Quick Thermal Conductivity Meter made by Kyoto Electronics Manufacturing Co., Ltd. The measurement sample must be at least 10 mm thick.

Sizes, MOQ

Product size

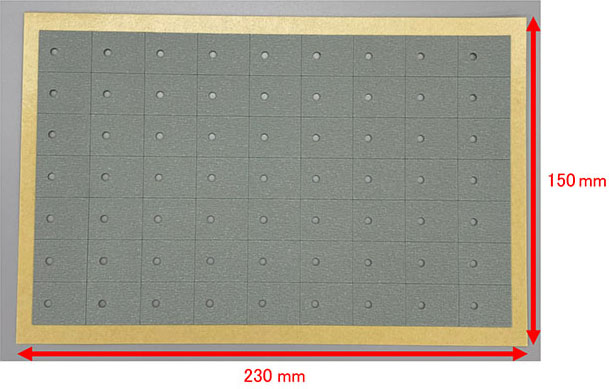

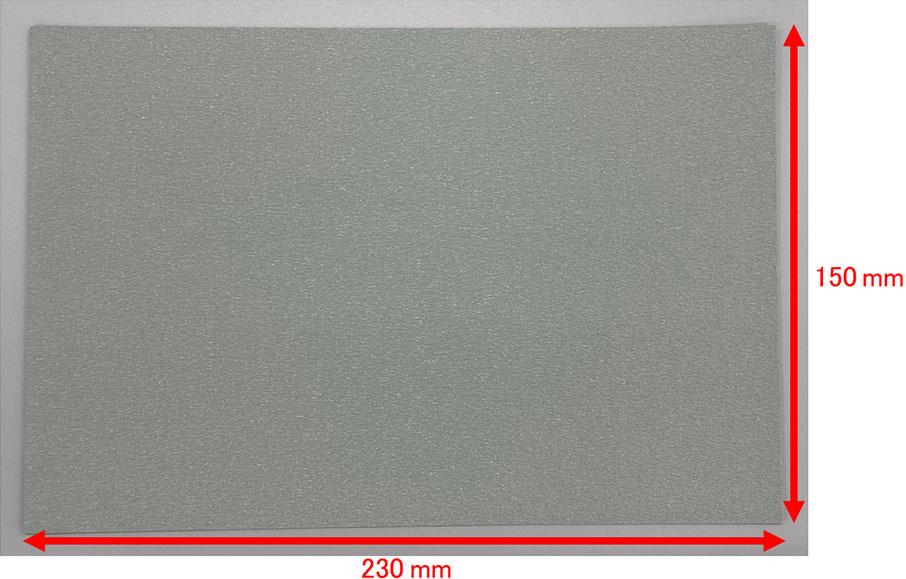

Custom cut, standard cut (150 x 230 mm), and non-cut (original sheet) are available.

Custom Sizes

- We cut out the greatest number of sheets possible (up to the size equivalent to the Standard Size (150 x 230 mm)).

- The minimum size is 5 x 5 mm.

- Sizes larger than 150 x 230 mm are also available upon consultation.

- We may charge a fee if it is necessary to adjust the punching die for custom sizes.

Standard size

- Our standard size is 150 x 230 mm (A5 size).

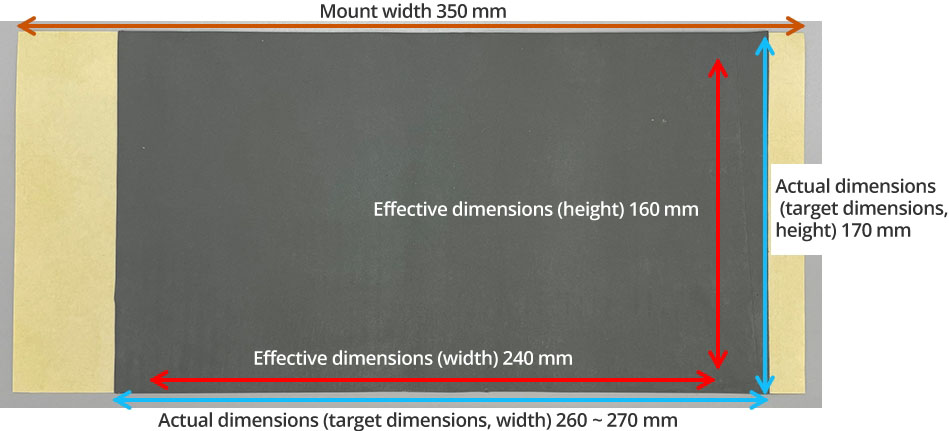

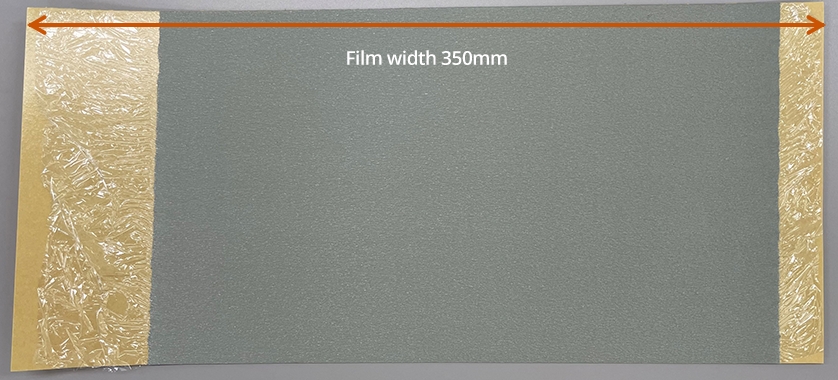

Non-cut original sheet

- The term “original sheet” refers to a sheet without cut edges. The effective dimensions are 160 x 240 mm.

- The film protrudes sideways from the original sheet of products with PET film (EE-RT, VHT, etc.) (film width is 350 mm).

MOQ

The MOQ is 50 sheets in standard cut size.

- (Note) Please contact us for information on packaging style.

Samples and estimates

Please use the following contact information to request samples and estimates.

Warnings

- This product is for general industrial use. Do not use for medical purposes (cooling pad, etc.) or for other special purposes.

- The product does not emit hazardous gas when burnt; however, please request disposal by a professional vendor.