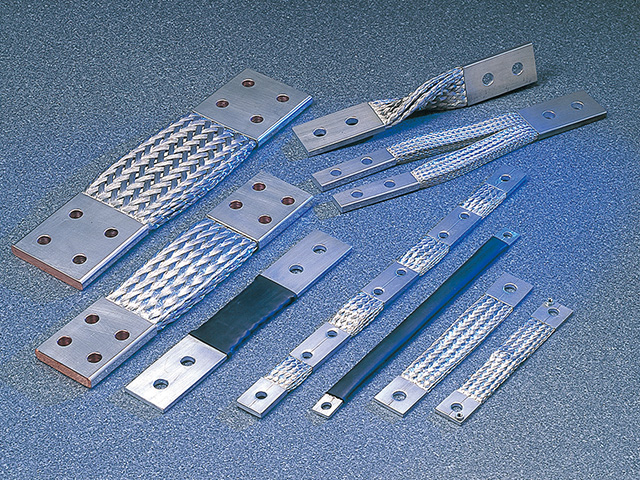

Flexible terminal

A soft conductor that is combined with a flat braided wire and has molded terminals on both ends

Lineup

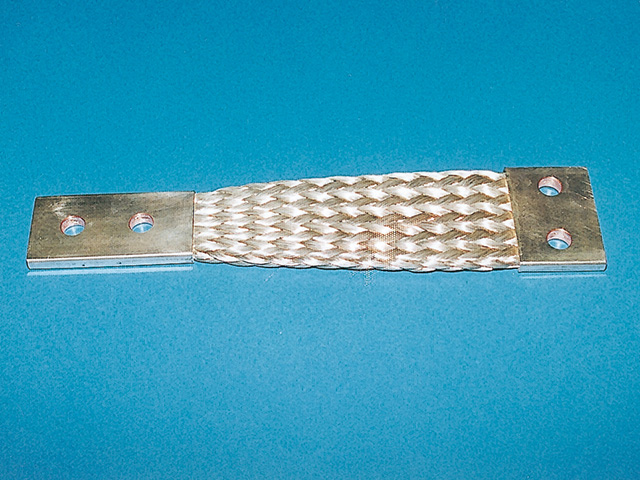

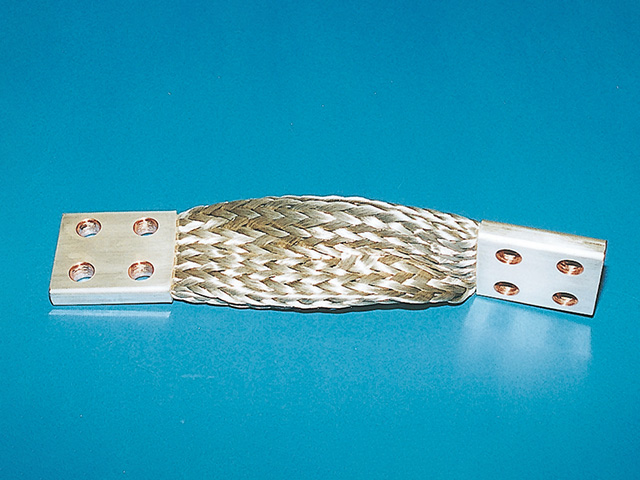

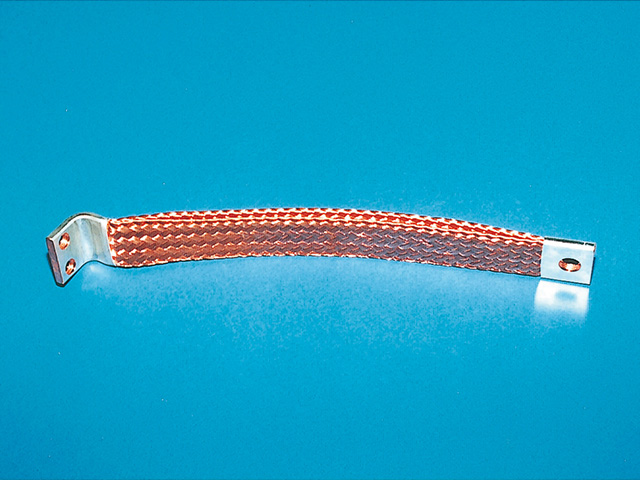

S-type flexible terminal

This electrical connection conductor consists of several rows or layers of tin-plated flat braided wires and has compression-molded terminals attached to both ends.

Features

- Superior flexibility

A flat braided wire is used for the flexible part to enable complex bending and twisting during installation. - Wide range of sizes

FEPS manufactures sizes ranging from small to large in terms of electric capacity and terminal shape. We can also manufacture sizes other than those listed in the catalog. Please contact us for further information. - Stable quality

We use a simplified structure and standardized processing method to produce products with stable quality. - FEPS can also manufacture products in which the flexible part is covered with an insulating tube

Variations

- S-500 type (width: 25)

- S-800 type (width: 40)

- S-1000 type (width: 50)

- S-1500 type (width: 75)

- S-2000 type (width: 100)

- S-3000 type (width: 150)

- S-4000 type (width: 200)

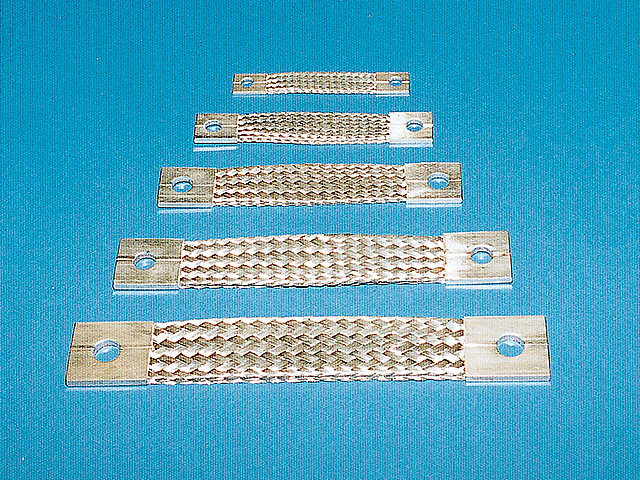

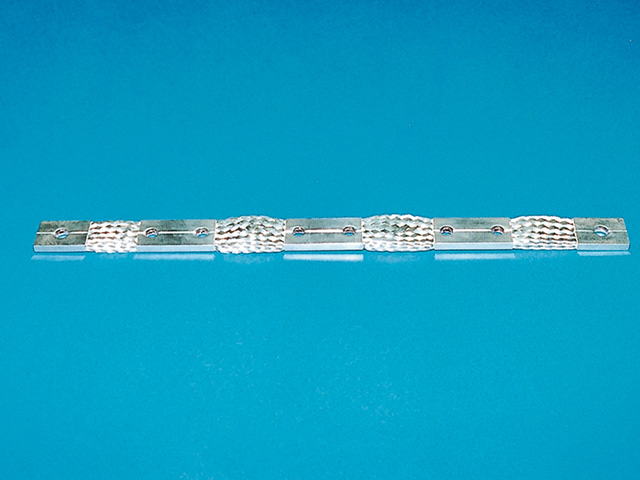

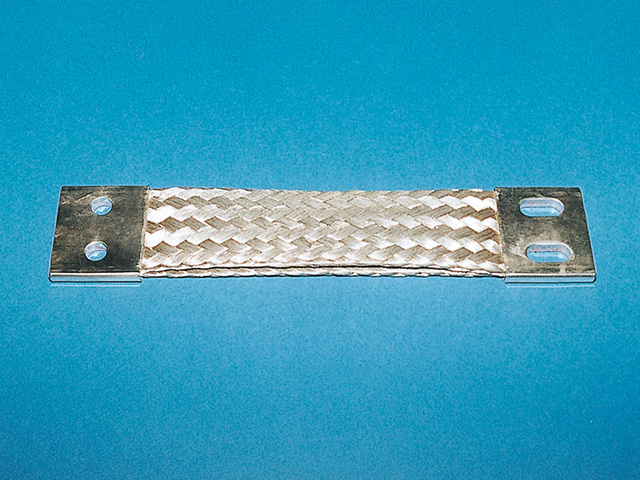

P-type flexible terminal

A small electrical connection conductor that consists of multiple layers of tin-plated flat braided wires and has terminals on both ends.

Features

- Superior flexibility

A flat braided wire with a diameter of 0.12 mm is used for the flexible part to enable complex installation that involves bending and twisting. - Stable quality

We use a simplified structure and standardized processing method to produce products with stable quality. - Supports mass production

- FEPS can also manufacture products in which the flexible part is covered with an insulating tube

Variations

- P-300 Type (width: 15)

- P-400 Type (width: 20)

- P-500 Type (width: 25)

- P-600 Type (width: 30)

- P-700 Type (width: 35)

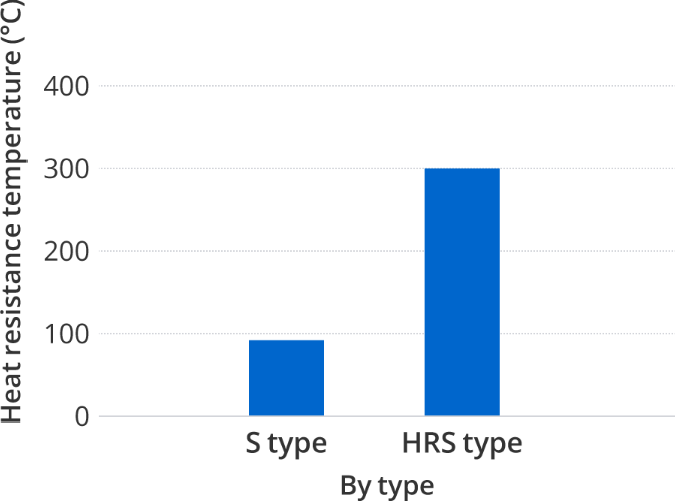

Heat-resistant flexible terminal with flat braided wire

The heat-resistant flexible terminal with flat braided wire is an electrical connection conductor made of heat-resistant element wire and has compression-molded terminals attached to both ends.

Features

- Superior flexibility

We improve flexibility by thinning the flat braided wire used in the flexible part. This enables complex installation that involves bending and twisting. - Superior heat resistance

This product achieves grater heat resistance than copper flat braided wire.

Heat resistance temperature: 300°C

Please note that this value is not guaranteed.

Comparison of Heat Resistance Temperature

- Please consult with us regarding sizes.

FEPS can manufacture sizes to meet your needs. Please contact us for further information.

Variations

- HRS-500 type Width: 25 mm (nominal cross-section area: 22 m²)

- HRS-500 type Width: 25 mm (nominal cross-section area: 30 m²)

- HRS-800 type Width: 40 mm (nominal cross-section area: 60m²)

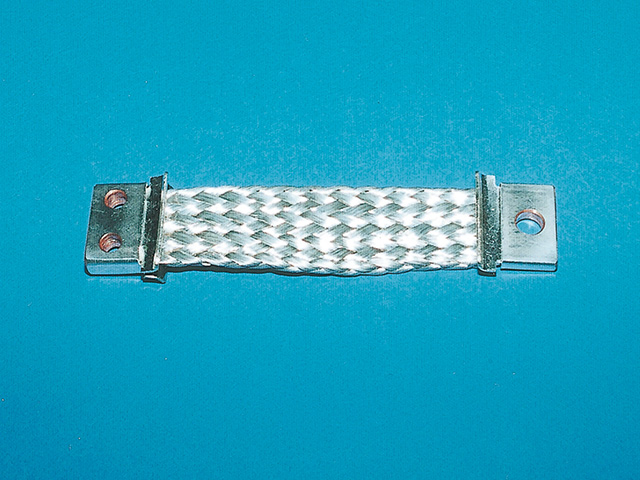

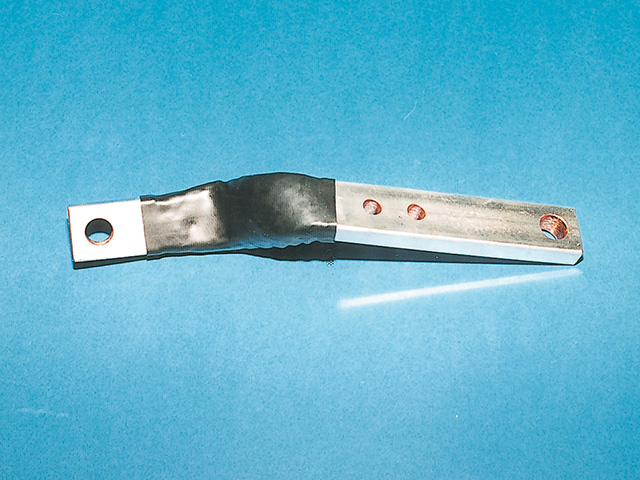

Flexible terminal with copper bars

This flexible terminal with copper bar is an electrical connection conductor. It is made by using electron beam welding to attach compression-molded terminals and copper bars to both ends of a tin-plated flat braided wire.

Features

- Superior flexibility

A flat braided wire is used for the flexible part to enable installation that involves bending. - Can be used in tight spaces

Electron beam welding is used to join the flexible terminal end and copper bar without any unevenness, so the terminal can be used in tight spaces.

Furthermore, copper bars are machinable and can be processed into various shapes. - Please consult with us regarding sizes and specifications.

FEPS will work to meet your needs for sizes and specifications. Please don't hesitate to consult with us.

Use

- Connections in the incoming panels and distribution panels of power equipment such as transformers and distribution equipment

- Inside of transportation equipment such as railway vehicles, aircraft, and automobiles

- Welders, heat treatment equipment, heating furnaces

- Mega solar equipment, PCS, power collection boxes, power distribution boxes

- Connection between storage battery cells

- Connections between bus duct and bus bar

- Thermal path and thermal strap for cooling heat transfer and heat dissipation

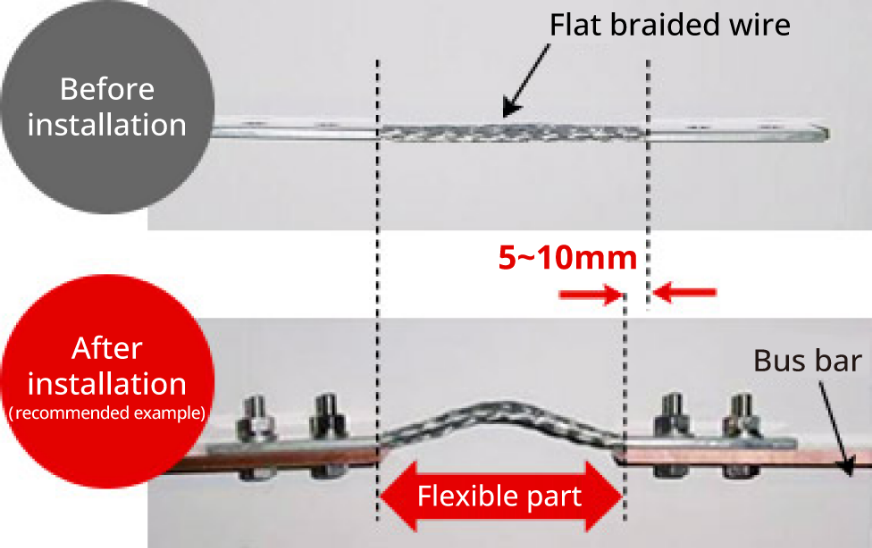

Important points when installing flexible terminals

Intended usage of flexible terminals

- (Note) Flexible terminals have various names such as flexible copper belts, shunt wires, flat braided wires, flat lead wires, and flexible conductors. Regardless of the name, they all have the same function.

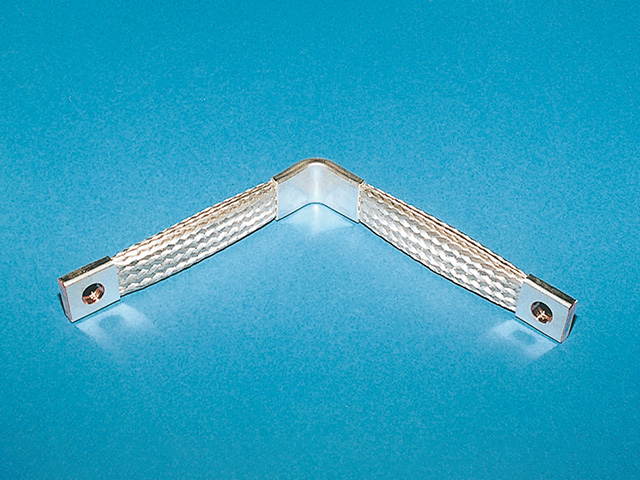

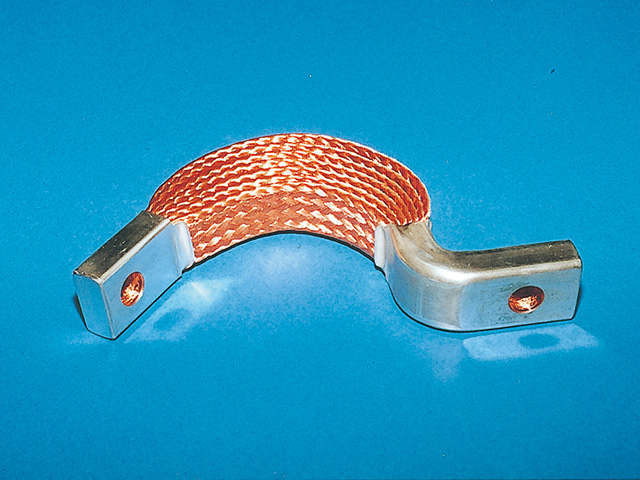

Examples of special usage of flexible terminals

- (Note) Depending on the size, some of the shapes listed above may not be available.

- (Note) Flexible terminals have various names such as flexible copper belts, shunt wires, flat braided wires, flat lead wires, and flexible conductors. Regardless of the name, they all have the same function.

Examples of special shapes of flexible terminals

- (Note) Flexible terminals have various names such as flexible copper belts, shunt wires, flat braided wires, flat lead wires, and flexible conductors. Regardless of the name, they all have the same function.

Inquiries on flexible conductors

FEPS also supports specifications and dimensions other than our standard products. Please inform FEPS of the following conditions in as much detail as possible.

- Model number

- Nominal cross-sectional area or current capacity

- Terminal width and bolt pitch of mating terminal to be connected to flexible conductor

- Total length

- Installation shape

- Surrounding conditions in area where flexible conductors are used

- Quantity